Title Paragraph

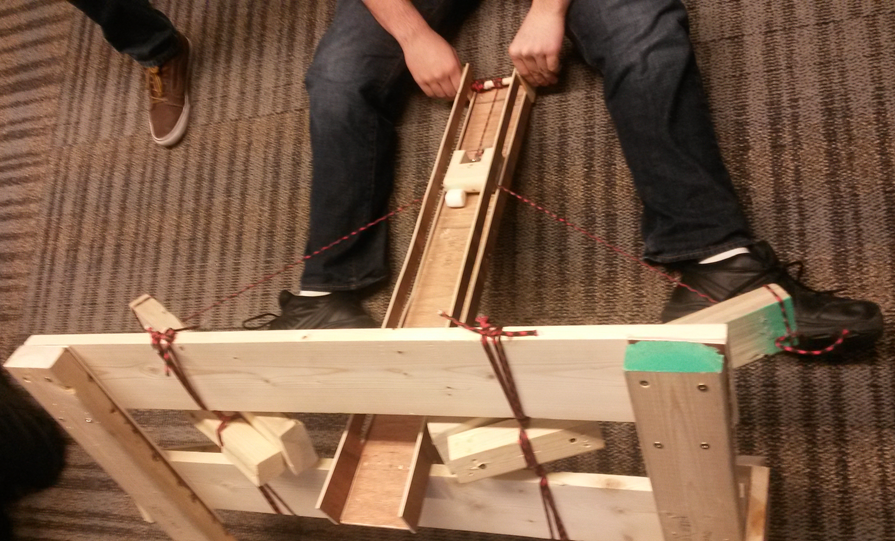

In this project, we made a launching device to shoot a marshmallow accurately but also far. This represented two challenges of the problem. We researched physical concepts such as torque to design the machine. The ballista has two arms which is connected by a string attached to the end of the arms. When you pull the string back, the arms rotate back as well. When you let the string go, the arms return to the starting position which brings the string back to its original position and ushers the marshmallow forward with it. To complete the challenge, we made a frame to with these arm elements to shoot the marshmallow forward. We started by making a mini model to help us understand some of the design concepts we will need to use.

|

| Mini model of desired machine |

Technological Concepts

For this project, there wasn't many concepts to research. One concept we spent time thinking about was torque. Torque is a driving force of rotation. Increased torque will result in greater power of the swinging arms of the ballista. With the increased power, the projectile will go farther. No other major concepts were explored. We had to use different way to make the ballista more sturdy. We used supporting beams to hold up the frame. Another thing we added for a sturdy base was pieces of wood on the side holding two other pieces of wood together. We would add a flat piece of wood on two by fours which would make the pieces stay together. This was added support to help prevent the ballista from falling apart.

Learning Goals

The goal for this project was to independently use our resources to figure out how to make the best machine to launch the marshmallow. We were given all the tools we could need but there was no directs research for the project. Based on what you wanted to create, you had to figure out what would be the design to maximize firing distance. We took time to research different aspects of the ballista and had to apply these concepts to our design. Time management with planning was key. Without a good plan, there would be too much redesign to get a good ballista. Time management came into play with thinking about research and actually creating the ballista. The other thing we learned about during this project was design and redesign. After initial construction of the ballista, there were things we had to figure out to make it work better.

Description

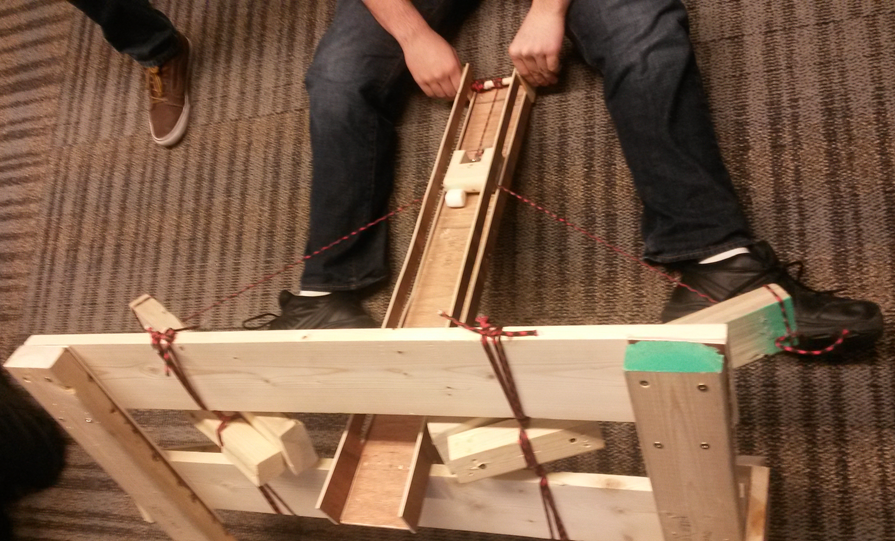

In this project, we made a ballista. A ballista is similar to a bow and arrow launching device. The basic idea of the ballista is a base holding two legs with a frame for arms, that deal with launching, and a launching runway through the center. The arms stick out from the center of a rectangular frame and are attached by a string that goes straight across from the end of one arm to the end of the other. The string is pulled back which pulls the arms back as well. The torque for that arms comes from the end of the arms near the center of the frame being twisted in string. The arm is snapped forward when the string is released, which takes the string from the end of the 'launch runway' back to the resting position and the projectile is ushered forward. This was our initial design. We added more the frame to make it more sturdy and also added some 2 by 4's to the base in the front to give it an angle. The angle helped us with shooting far distances.

|

| Ballista in resting position |

|

| Ballista when loaded |

Positive Feedback

The ballista we made ended up being very good. After a lot redesign, the ballista could shoot up to 28 feet. The accuracy was above average as compared to the rest of the class. We were able to get the marshmallow into the bin twice of our three tests on the final day. We also met most of our set goals in the beginning. We wanted to focus on accuracy. The ballista could successfully shoot the distance we wanted with little testing and marked positions of pulling the string back. We also used all of our time tweaking the machine to make it the best we could. We used our time efficiently to give us enough days to get everything just right and still have the paperwork done. This was also an accomplishment for us since we thought we were not going to be able to make all the changes we need to get it to work right.

Redesign Paragraph

If given another chance, we would try to make the ballista more clean cut. In the end, after all the redesign, the ballista was not aesthetically pleasing. To make the machine better, it would have been beneficial to spend more time planning. We did enough research to know how it works, but we were hoping that the initial design based on the mini model would be able to shoot as far as we needed it to. Once we got going, we found that it wasn't working as planned. If I could redo it, I would have stopped at this point and looked more into the problem. It would have been easier to address all issues at once instead of stumbling upon new problems each day. The ballista could have been more powerful, sturdy, and aesthetically pleasing if were were able to do less correcting of problems.

Technological Resources

Throughout the process, we used many different things. In the beginning, we did research on the computer. We found many different designs for ballistas online. We combined different ideas to create one we felt would work well. We then had as much wood as we needed to create our ballista. We had limited selections when it came to adhesives. The screws we were using we not always long enough and we didn't have the greatest nails available. This was an issue when it came to cutting the wood pieces and assembling the ballista. We would have to be careful the way we planned to put it together to make sure we would be able to make it sturdy. We had limited time, as well. This was not that much of an issue for us since we got started quickly and left plenty of time to fix any problems.

Biggest Challenge

One of the biggest challenges was getting enough power to ballista. We kept having issues with how far the ballista could shoot. To begin with, the ballista could only shoot about 10 feet. We needed it to shoot at least 25 feet. We kept taking the machine apart and twisting the arms in the ballista more to add more power. The wood was not strong enough to withstand the force of the string, though. We added more string to the wood to increase the tension which would decrease the amount of times we needed to twist the string. This fix helped the power substantially. We ended up also getting thicker wood that would allow us to twist the string more. These small changes aided the power enough to a point which our farthest shooting distance was 28 feet. It took us many days to make the adjustments since it was difficult to take apart the ballista, but in the end it worked well.

What I Learned From the Project

From this project, I learned about the redesign process. Before, I hadn't done much redesign because I didn't have much time make changes to projects. This time, we had plenty of time and plenty of problems for fixing. With redesign, you have to be careful because you don't want to create more problems. The other aspect is with redesigning is the appearance part. Just adding a bunch of things to the project took away the feeling of the project being one piece. In the end, it all seemed like a bunch of pieces randomly put together. In some ways, we were careful about the looks with taking it apart to add a piece or to replace a broken two by four, but many of the times we just added things to the frame to improve performance. Redesign takes time for thought. You need to address specific problems and make a list of possible solutions before you can start changing your machine. In the beginning, we just tried different things to see what would work. By the end, we figured out we should do more research into the problem before changing the project because it amounts to less work in the end. Redesigning was essential to this project, so I became very familiar with the ups and downs of the process.